中文版

From Chemicals-technology.com

A group of scientists at Genomatica and Braskem have announced that they have produced butadiene through a direct, bio-based process in a lab.

The companies have been producing butadiene in lab scale since June 2015 at Genomatica’s innovation centre in San Diego and Campinas.

In 2013, both Genomatica and Braskem joined to develop a commercial process for on-purpose production of butadiene from renewable feedstocks.

During the course of their programme, the team at Genomatica and Braskem has successfully developed a microorganism that consumes sugar and converts it to butadiene at lab scale, in two-litre fermenters.

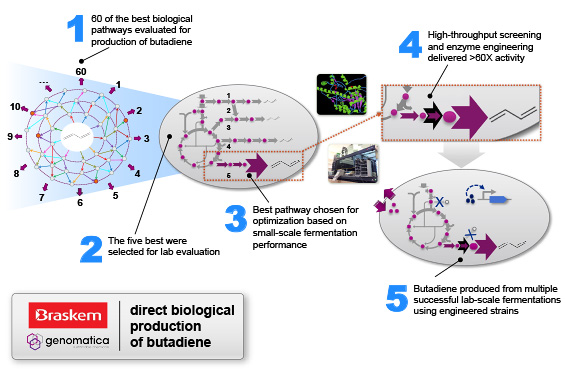

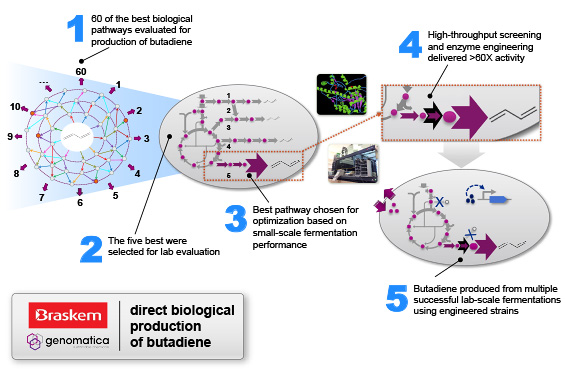

Genomatica has been able to recognise 60 possible biological pathways with which a microorganism can make butadiene, theoretically.

Out of those 60 pathways, five were selected for experimental confirmation.

The programme further helps to boost intellectual knowledge of Braskem and Genomatica.

Genomatica R&D senior vice-president Nelson Barton said: “Our joint team has made good use of Genomatica’s integrated bioengineering platform, including its computational techniques and high-throughput cloning and screening, to quickly hit a key milestone.

“Our ‘rational’ approach to strain design should enable faster, more predictable scale-up and better economics as we advance the programme.”

Butadiene is a used in the production of rubber for tires, electrical appliances, footwear, plastics, asphalt, building materials, and latex and a renewable butadiene expects to lower carbon footprint in the industrial output.

In July, Genomatica partnered with American company Cargill to develop renewable chemicals for industrial applications.

With the partnership, both the companies are expected to produce a cost-effective source of carbohydrate feedstocks, as well as co-location support services to chemical producers, distributors and users.

Image: Braskem and Genomatica have successfully achieved direct biological production of butadiene at lab scale. Photo: courtesy of Genomatica, Inc.

您必须登录才能发表评论。