INTRODUCTION 介绍

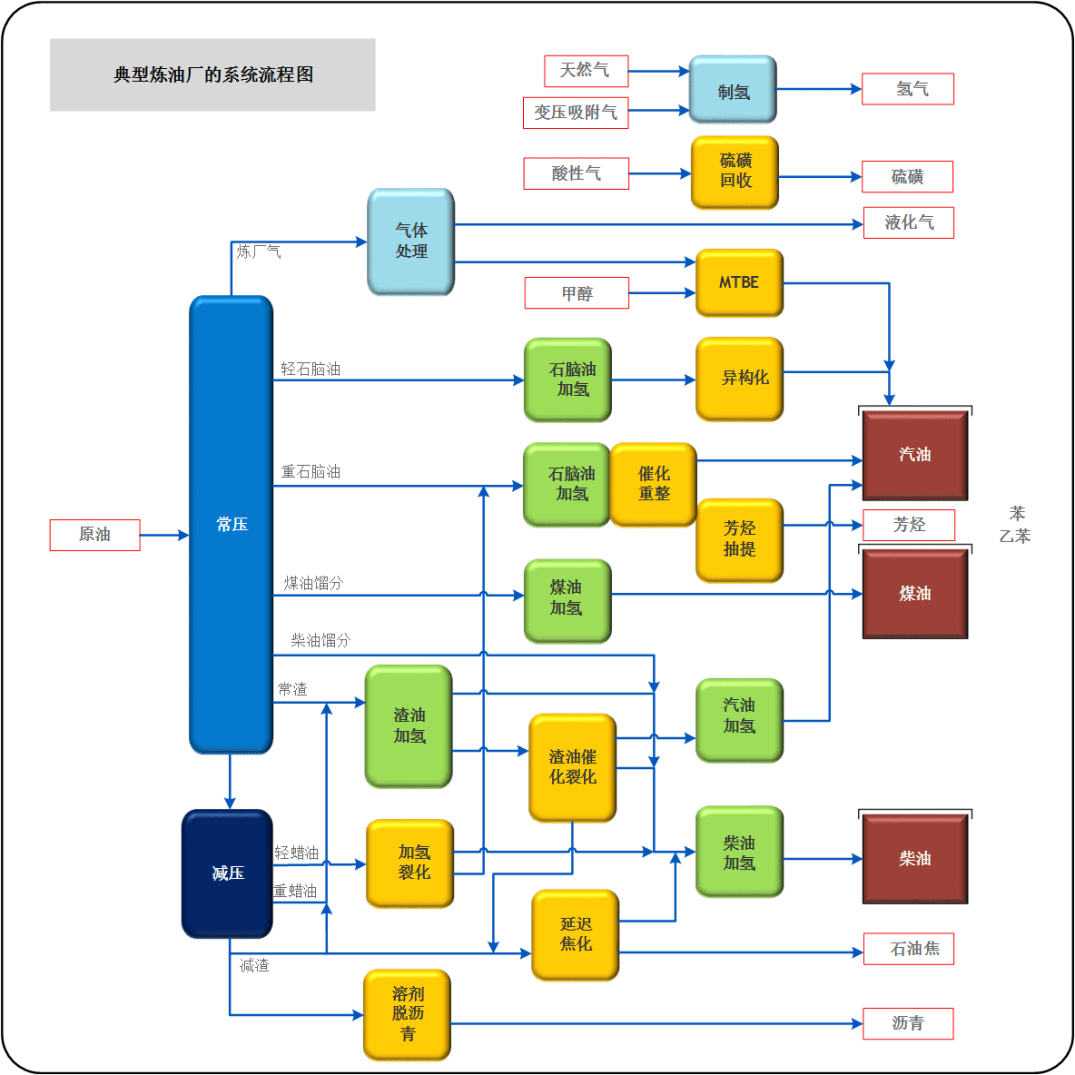

Petroleum refining begins with the distillation, or fractionation, of crude oils into separate hydrocarbon groups. The resultant products are directly related to the characteristics of the crude processed. Most distillation products are further converted into more usable products by changing the size and structure of the hydrocarbon molecules through cracking, reforming, and other conversion processes as discussed in this website these converted products are then subjected to various treatment and separation processes such as extraction, hydrotreating, and sweetening to remove undesirable constituents and improve product quality. Integrated refineries incorporate fractionation, conversion, treatment, and blending operations and may also include petrochemical processing.

Petroleum refineries are very large industrial complexes that involve many different processing units and auxiliary facilities such as utility units and storage tanks. Each refinery has its own unique arrangement and combination of refining processes largely determined by the refinery location, desired products and economic considerations. There are most probably no two refineries that are identical in every respect.

REFINING OPERATIONS

Petroleum refining processes and operations can be separated into five basic areas:

- Fractionation (distillation) is the separation of crude oil in atmospheric and vacuum distillation towers into groups of hydrocarbon compounds of differing boiling-point ranges called “fractions” or “cuts.”

- Conversion processes change the size and/or structure of hydrocarbon molecules. These processes include:

- Decomposition (dividing) by thermal and catalytic cracking;

- Unification (combining) through alkylation and polymerization; and

- Alteration (rearranging) with isomerization and catalytic reforming.

- Treatment processes are intended to prepare hydrocarbon streams for additional processing and to prepare finished products. Treatment may include the removal or separation of aromatics and naphthenes as well as impurities and undesirable contaminants. Treatment may involve chemical or physical separation such as dissolving, absorption, or precipitation using a variety and combination of processes including desalting, drying, hydrodesulfurizing, solvent refining, sweetening, solvent extraction, and solvent dewaxing.

- Formulating and Blending is the process of mixing and combining hydrocarbon fractions, additives, and other components to produce finished products with specific performance properties.

- Other Refining Operations include: light-ends recovery; sour-water stripping; solid waste and wastewater treatment; process-water treatment and cooling; storage and handling; product movement; hydrogen production; acid and tail-gas treatment; and sulfur recovery. Auxiliary operations and facilities include: steam and power generation; process and fire water systems; flares and relief systems; furnaces and heaters; pumps and valves; supply of steam, air, nitrogen, and other plant gases; alarms and sensors; noise and pollution controls; sampling, testing, and inspecting; and laboratory, control room, maintenance, and administrative facilities.

Note:

1. Process unit:

CDU – Crude Distillation unit VDU – Vacuum Distillation unit

GFU – Gas Fractionation unit NHT – Naphtha Hydrotreating

KHT – Kerosene Hydrotreating GHT – Gasoline Hydrotreating

DHT – Diesel Hydrotreating RDS – Residue Desulfuration

HC – Hydro Cracking RFCC – Residue Fluid Catalytic cracking

DCU – Delayed coking SRU – Sulfur Recovery Unit

HPU – Hydrogen Production Unit SDU – Solvent Deasphalting unnit

ISO – Isomerization unit

FEEDSTOCK

BASICS OF CRUDE OIL.

- Crude oils are complex mixtures containing many different hydrocarbon compounds that vary in appearance and composition from one oil field to another. Crude oils range in consistency from water to tar-like solids, and in color from clear to black. An “average” crude oil contains about 84% carbon, 14% hydrogen, 1%-3% sulfur, and less than 1% each of nitrogen, oxygen, metals, and salts. Crude oils are generally classified as paraffinic, naphthenic, or aromatic, based on the predominant proportion of similar hydrocarbon molecules. Mixed-base crudes have varying amounts of each type of hydrocarbon. Refinery crude base stocks usually consist of mixtures of two or more different crude oils.

- Relatively simple crude oil assays are used to classify crude oils as paraffinic, naphthenic, aromatic, or mixed. One assay method (United States Bureau of Mines) is based on distillation, and another method (UOP “K” factor) is based on gravity and boiling points. More comprehensive crude assays determine the value of the crude (i.e., its yield and quality of useful products) and processing parameters. Crude oils are usually grouped according to yield structure.

- Crude oils are also defined in terms of API (American Petroleum Institute) gravity. The higher the API gravity, the lighter the crude. For example, light crude oils have high API gravities and low specific gravities. Crude oils with low carbon, high hydrogen, and high API gravity are usually rich in paraffins and tend to yield greater proportions of gasoline and light petroleum products; those with high carbon, low hydrogen, and low API gravities are usually rich in aromatics.

- Crude oils that contain appreciable quantities of hydrogen sulfide or other reactive sulfur compounds are called “sour.” Those with less sulfur are called “sweet.” Some exceptions to this rule are West Texas crudes, which are always considered “sour” regardless of their H2S content, and Arabian high-sulfur crudes, which are not considered “sour” because their sulfur compounds are not highly reactive.

Although crude oil assays evaluate various chemical properties of the oil, the two most important properties determining a crude’s value are its density (measured as API specific gravity) and its sulfur content (measured per mass).

# Crude categorized by relative density:

Light crude oil relative density < 0.851, API >34

Medium crude oil relative density 0.851 ~ 0.930, API 34 ~20

Heavy crude oil relative density 0.930 ~ 0.996, API 20 ~ 10

Extra heavy crude oil relative density >0.996, API<10

# Crude categorized by sulfur content (wt%)

Sweet crude: < 0.5%

Sour crude: 0.5 ~ 2.0%

High sulfure crudes: > 2.0%

For more information, please check

https://en.wikipedia.org/wiki/Petroleum#Crude_oil

PRODUCTS

To understand the diversity contained in crude oil, and to understand why refining crude oil is so important in our society, look through the following list of general products that come from crude oil:

Petroleum gas – used for heating, cooking, making plastics, small alkanes (1 to 4 carbon atoms) commonly known by the names methane, ethane, propane, butane.

Fuel gas, (C1 to C3) separated at atmospheric pressure from rest of the crude oil is used in the refinery as fuel gas, mixture of methane, ethane and propane. Fuel gas is used for various purposes in the refinery including blanketing gas.

Liquefied Petroleum Gas (LPG), mixture of propane and butane (C3+C4). These gases separated from the top of Atmospheric Distillation Unit (or Crude Distillation Unit – CDU) are liquefied under pressure and sold as cooking fuel..

Naphtha – intermediate that will be further processed to make gasoline, mix of 5 to 9 carbon atom alkanes, boiling range = 140 to 212 degrees Fahrenheit / 60 to 100 degrees Celsius.

Gasoline – motor fuel, liquid, mix of alkanes and cycloalkanes (5 to 12 carbon atoms), boiling range = 104 to 401 degrees Fahrenheit / 40 to 205 degrees Celsius

Jet Fuel / Kerosene – liquid, mix of alkanes (10 to 18 carbons) and aromatics, boiling range = 350 to 617 degrees Fahrenheit / 175 to 325 degrees Celsius. Most of refinery produced kerosene can be used as high quality Aviation Turbine Fuel (ATF). Kerosene is less volatile than gasoline and separated from crude oil after the naphtha have boiled off.

Diesel – liquid, alkanes containing 12 or more carbon atoms, boiling range = 482 to 662 degrees Fahrenheit / 250 to 350 degrees Celsius. Diesel is primarily used as transportation fuel in compression ignition engines in various types of vehicles. A kind of diesel also known as ‘gas oil’ can be domestically used for heating. Diesel is less volatile (or heavier) than gasoline and kerosene.

Lubricating oil – used for motor oil, grease, other lubricants, liquid, long chain (20 to 50 carbon atoms) alkanes, cycloalkanes, aromatics, boiling range = 572 to 700 degrees Fahrenheit / 300 to 370 degrees Celsius.

Fuel oils – liquid, long chain (20 to 70 carbon atoms) alkanes, cycloalkanes, aromatics, boiling range = 700 to 1112 degrees Fahrenheit / 370 to 600 degrees Celsius. The lighter grades of fuel oil are used as transportation fuel for compression engines with low velocities and heavier grades of fuel oil are used as fuel to boilers, power stations etc.

Residuals – coke, asphalt, tar, waxes; starting material for making other products, Solid, multiple-ringed compounds with 70 or more carbon atoms, boiling range = greater than 1112 degrees Fahrenheit / 600 degrees Celsius.

Bitumen/Asphalt, this is the heaviest cut of hydrocarbons left at the bottom after boiling off all the hydrocarbons usable as fuels. It is primarily used as road covering material, but can also be used as a waterproofing material.

Petroleum coke, that is relatively pure carbon and can be sold for use as fuel (i.e. fuel grade coke), or for the manufacture of dry cells, electrodes, etc.

Sulfur – Crude oil production is generally accompanied by H2S gas. This H2S gas is separated from rest of the crude oil along with fuel gas – methane and ethane (C1&C2). H2S is separated from the fuel gas in Amine Recovery Unit (ARU) and further, pure sulfur is separated in the Sulfur Recovery Unit (SRU). This sulfur in liquefied form is sold to the fertilizer manufacturers.

REFERENCE

- SECTION IV: CHAPTER 2, OSHA Technical Manual

- Refinery design and engineering by Sinopec press, 2014.

- https://en.wikipedia.org/wiki/Petroleum#Crude_oil

您必须登录才能发表评论。